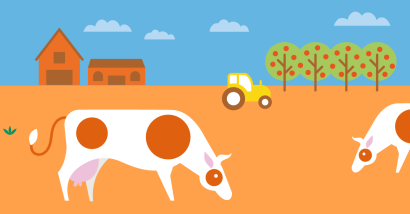

Food production

Where do we go from here?

When humans first became settled agriculturists and started to grow food for use all year round, we developed an intimate knowledge and a close involvement with the sources of our food. The industrial revolution, and more recently, modern food technology changed all this.

Many people today are far removed from the sources of food they eat on a daily basis. Technological progress in food manufacturing and recent discoveries in nutritional science have resulted in increasingly high food quality standards and enormous food variety.